Back to top

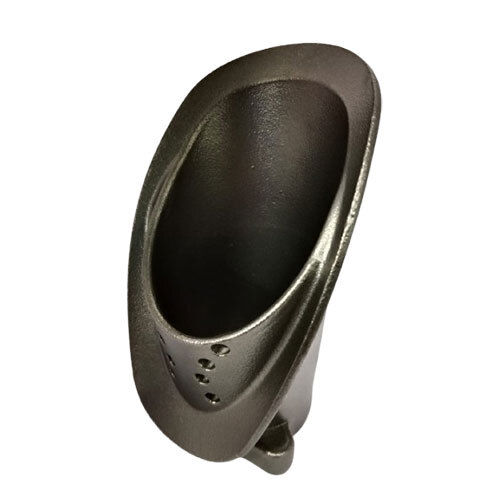

Trusted leader in the market for manufacturing and supplying Small Size Valve Casting, Auto Parts Casting, Valve Body End Casting, Submersible Pump Impeller, and many other products.

Dev Metacast is a company, which has always remained in industry talks due to our continuous focus on innovation and rapid transformation. We started our operations as a Joint Family Members in 1987 by trading and manufacturing a range of SS Sleeves that are used as a part of Submersible Pump. Later on, we developed manufacturing facilities for Submersible Thrust Bearing to have Monopoly Items across India. Post that, to develop high quality castings and meet the requirements of customers, in 2001, we started our Shell Molding Foundry. We also developed our investment casting process in 2007 and added several types of casting products in our portfolio. With all these, currently, our group has rich experience at dealing Submersible Thrust Bearing, Shell Molding Castings and Investment Casting and Machining.

In 2018, the entire management of our group companies got changed and with that we started Dev MetaCast. The company has developed a cutting-edge Investment Casting Plant for meeting the market demands for high quality castings including Auto Parts Casting, Valve Body End Casting, Small Size Valve Casting, Submersible Pump Impeller, and many others. We later on developed a strong reputation for ourselves in the domain for providing supreme quality and cost-effective casting solutions to customers across the world. Our current casting manufacturing capacity is of DMC is 50 MT./month, allowing us to meet the demands of maximum number of customers. We not just provide products of international standards but also customized one with the spirit of continual innovation and unceasing improvement.

Our USPs

Our Quality Policy

Over the years, we have worked with customers from different industries and regions and have gained rich knowledge and experience of their requirements. We have adopted strict quality control managing system as per the ISO 9001-2015 certification, granted by TUV Nord. As per the system, we follow strict quality standards and never stop our pursuit of constant improvement. Each of our team member focuses on gaining customer satisfaction, delivering superb quality and quickly responding to the customers.

Our Facts

In 2018, the entire management of our group companies got changed and with that we started Dev MetaCast. The company has developed a cutting-edge Investment Casting Plant for meeting the market demands for high quality castings including Auto Parts Casting, Valve Body End Casting, Small Size Valve Casting, Submersible Pump Impeller, and many others. We later on developed a strong reputation for ourselves in the domain for providing supreme quality and cost-effective casting solutions to customers across the world. Our current casting manufacturing capacity is of DMC is 50 MT./month, allowing us to meet the demands of maximum number of customers. We not just provide products of international standards but also customized one with the spirit of continual innovation and unceasing improvement.

Our USPs

- Casting Capacity up to 50 MT. Per month

- Can perform heat treatment work as per the specifications of customers or as per the International Standard Specifications.

- Provide uniform quality castings by following our strict work processes and programme.

- Have sound facilities for Sand Blasting, Shot Blasting, Electro Polishing, Heat Treatment, etc.

- Modern facilities for packaging and labeling.

- Ability to manufacture castings from several Austenitic Stainless Steel (CF8, CF3, CF3M, Duplex, Super Duplex, CF8M, CF8C, CB7CU1 and all other SS metals.) and Martensitic Stainless Steel (CA40 (420), CA15 (410))

- Ability to produce products from special alloys as per the International Standards and specifications defined by customers. (Specifications like DIN, ASTM, SAE & AISI.)

Our Quality Policy

Over the years, we have worked with customers from different industries and regions and have gained rich knowledge and experience of their requirements. We have adopted strict quality control managing system as per the ISO 9001-2015 certification, granted by TUV Nord. As per the system, we follow strict quality standards and never stop our pursuit of constant improvement. Each of our team member focuses on gaining customer satisfaction, delivering superb quality and quickly responding to the customers.

Our Facts

- Family owned company

- Casting Size: 50 gm. to 100 Kg.

- Turnover: 100 Million INR

- Number of employees: More than 100

- Customers: From the Pump Valve and Motor Industry & Metalworking Industry

Most Popular Products

Dev Metacast

GST : 24AAQFD2929M1Z0

GST : 24AAQFD2929M1Z0

Block No. - 808, Mansa-Vijapur Highway, Motipura bus stop, District:- Gandhinagar,Vijapur - 382855, Gujarat, India

Phone :08045814922

|

Dev Metacast

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |